SmartRack™ Enables Factory Automation

SmartRack

A complete factory automation workstation optimized for traceability, equipment control, and local data acquisition.

Key features

- Compact footprint: starts at 1ft x 1ft, typical racks 3ft x 4ft; modular chassis for expansion.

- Protocols: SECS/GEM and HSMS for semiconductor lines, plus Serial (RS-232/RS-485), Modbus RTU/TCP, TCP/IP, and REST APIs for modern integrations.

- Flexible I/O: Up to 14 digital sensor inputs (5V 3-wire), expandable analog I/O, and configurable digital outputs/relays.

- RFID support: 13.56 MHz (ISO15693 family) readers with configurable read/write operations and tag filtering to support ID cards, labels, and embedded tags.

- Label printing: Integrates with Zebra (ZPL/EPL), SATO and Epson printers via network or USB; supports template-based and variable data printing.

- Web UI & API: Modern web interface with role-based access, live status via WebSocket, and a documented REST API for automation and MES integration.

- Local event storage & export: onboard history (SQLite or MySQL backends), CSV/JSON export and secure transfer options to analytics or MES.

Technical specifications (typical)

- Controller: Industrial embedded x86/ARM, 2–8 CPU cores, 4–16 GB RAM, 32–256 GB flash/SSD (configurable)

- I/O: 14 digital inputs (5V), expandable analog inputs, optional relay outputs

- Network: Dual Ethernet (1Gbps), optional Wi-Fi, TLS-secured HTTP(S)

- Storage & DB: Local time-series event store, export via REST, retain policies configurable

- Power: 110–240VAC (typical), optional DC variants

- Security: TLS 1.2+, user authentication, role-based authorization, audit logs

Integration example (REST event)

Show/Hide integration example

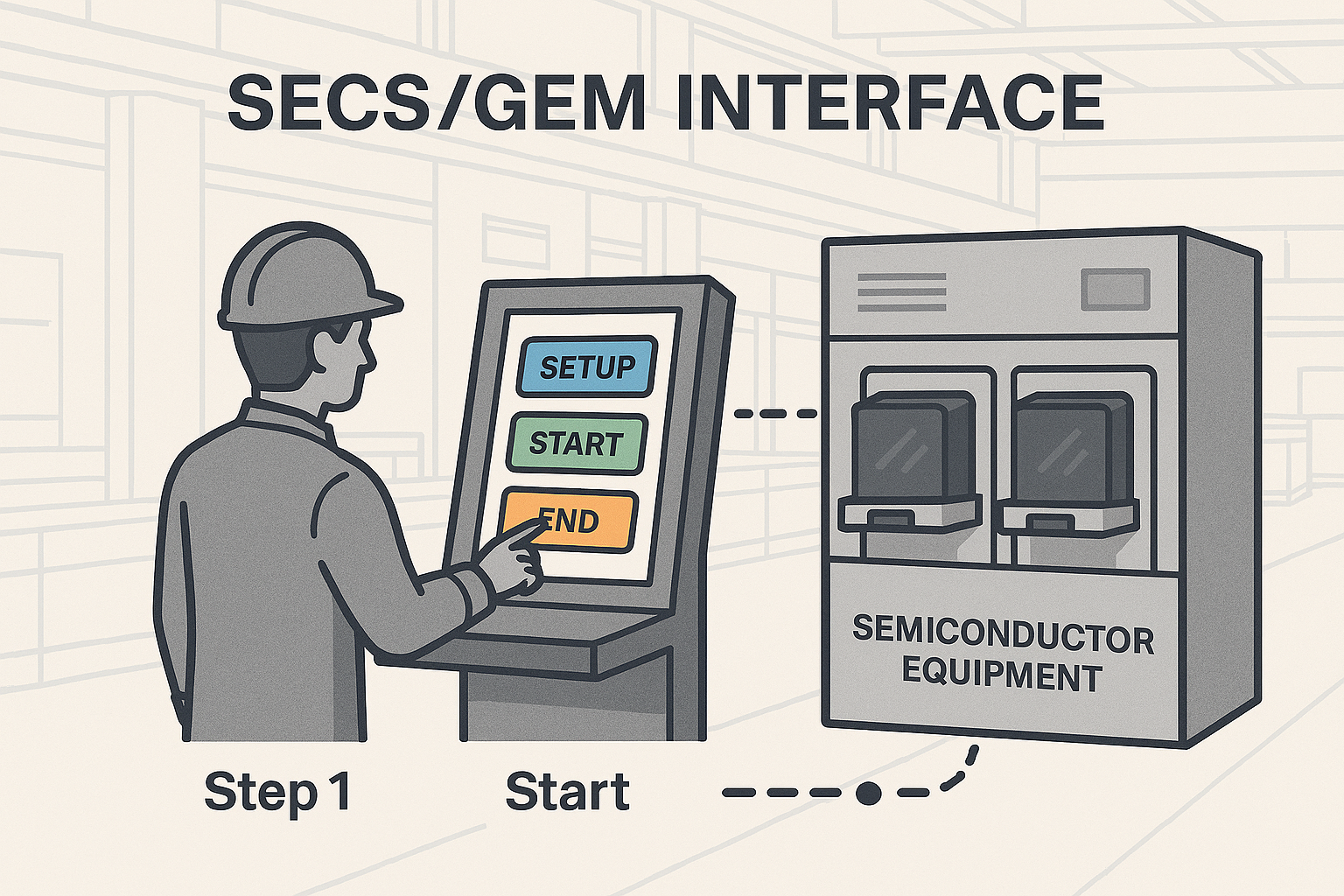

Equipment Controllers

Deterministic equipment controllers focusing on the full control lifecycle: setup, start, pause/resume, and end-of-job handling with integrated recipe and data management.

Control lifecycle (setup → start → end)

- Setup: Pre-flight checks, parameter validation, fixture configuration, and dry-run verification to ensure safe start conditions.

- Start: Atomic start command that initiates the recipe, arms I/O, begins telemetry, and emits a job_start event to MES.

- Pause/Resume: Safe pausing mechanics with state checkpointing and operator-controlled resume.

- Stop/End: Graceful end-of-job sequence capturing final metrics, closing files, printing labels, and optionally placing parts in hold state if errors occur.

Recipe management

- Versioned recipes stored in the device DB with validation, approvals, and audit trails.

- Recipe structure supports sequential steps, conditional branching, nested subroutines, and parameter templates.

- Operations: upload/validate/activate/snapshot/rollback via REST API or MES interfaces.

Recipe example (JSON)

Show/Hide integration exampleData collection & telemetry

- High-resolution telemetry with configurable sampling rates and software filtering; local time-series storage with retention policies.

- Structured events: job_start, step_start, step_end, telemetry_sample, alarm — all emitted as JSON with timestamps and sequence numbers.

- Export options: REST endpoints, WebSocket streams, MQTT/Kafka pushes, and batch CSV/JSON downloads for analytics ingestion.

API & command examples

Show/Hide integration exampleAlarms, safety & audit

- Hardware watchdogs, safety interlocks and configurable alarm severities with automatic hold behavior.

- Full audit trail for recipe changes, user actions, and job lifecycle events for compliance and forensics.

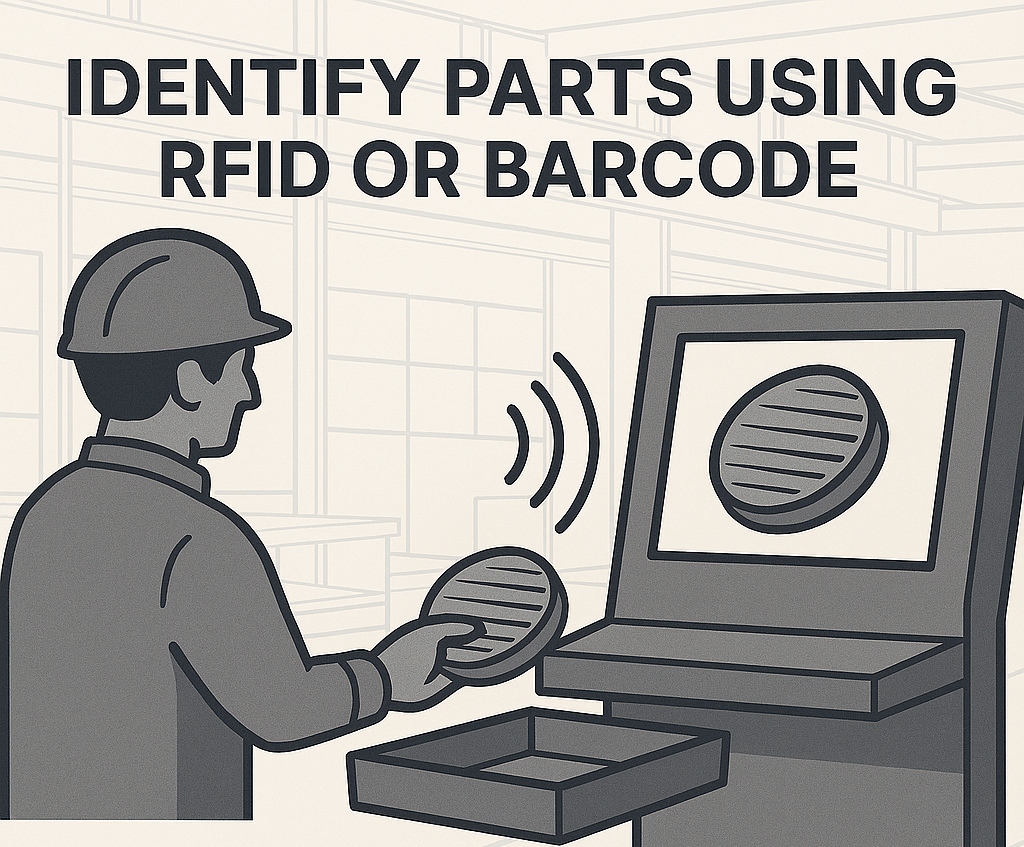

Barcode & RFID Tracking

Industrial-grade barcode scanners and 13.56MHz RFID readers tuned for product tracking and high-throughput lines.

Technical details

- RFID: 13.56 MHz (ISO15693 family), configurable power/read filters, anti-collision support for high-density tag reads.

- Barcodes: Support for 1D/2D symbologies (Code 128, Code 39, QR, DataMatrix) and configurable normalization rules.

- Tag data handling: read/write tag memory, NDEF payloads when applicable, and consistent UID mapping into MES IDs.

- Performance: optimized batching and event debouncing to avoid duplicate reads and ensure accurate traceability.

Sample event (CSV / JSON)

Show/Hide integration example

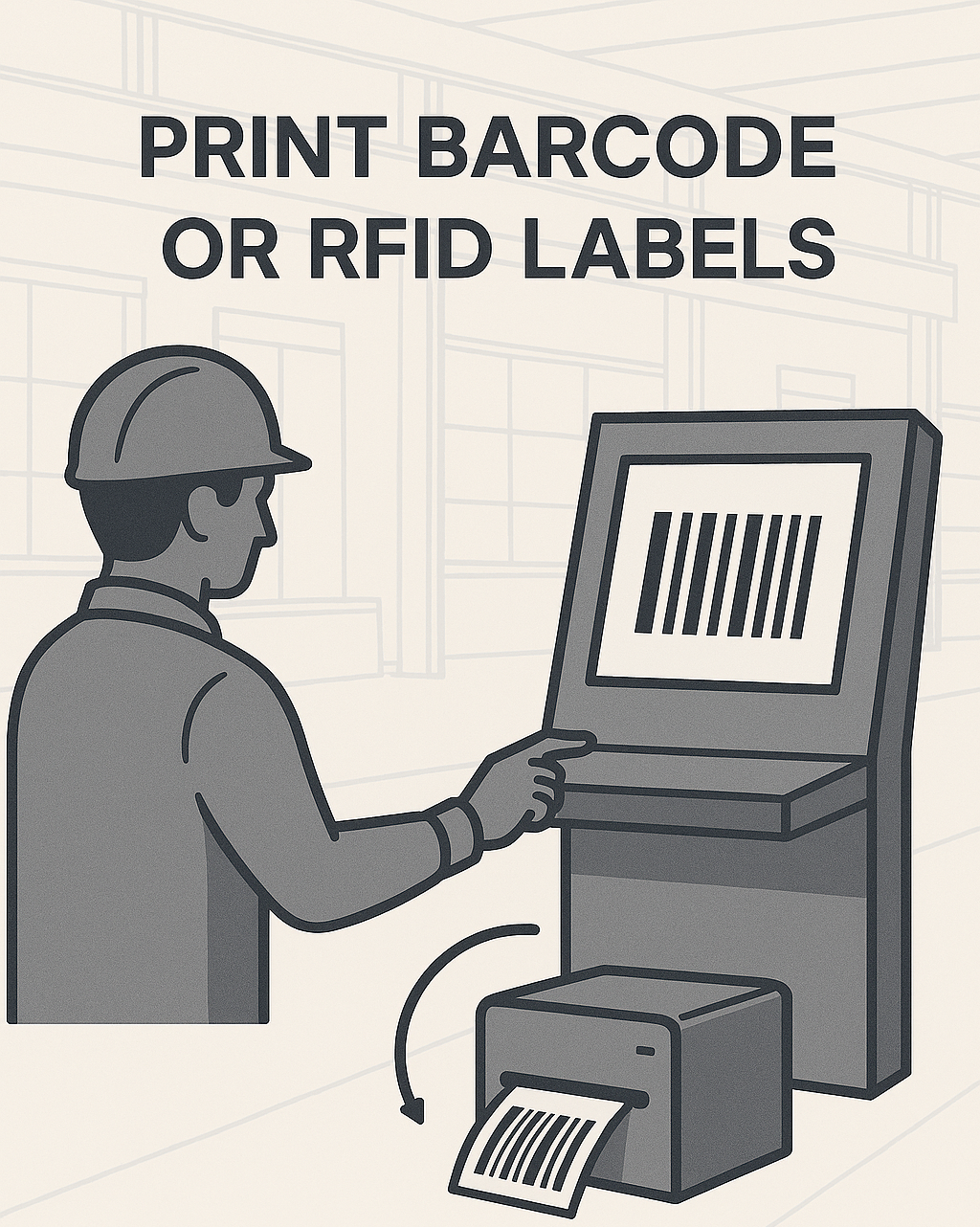

Printing

Robust label printing solutions for barcode and RFID labels, with template-driven variable data and automated print workflows.

Technical notes

- Printer support: Zebra (ZPL/EPL), SATO, Epson; supports network (TCP/IP), USB, or Windows print drivers.

- Templates: server-side templating for variable fields, image embedding and multi-line barcodes.

- Label formats: configurable sizes, resolutions (203/300/600 dpi) and encoding for RFID label programming.

- Integration: print-on-event via REST calls or direct LPR/IPP job submission; reliable retry and job status reporting.

Example ZPL snippet

Show/Hide integration example

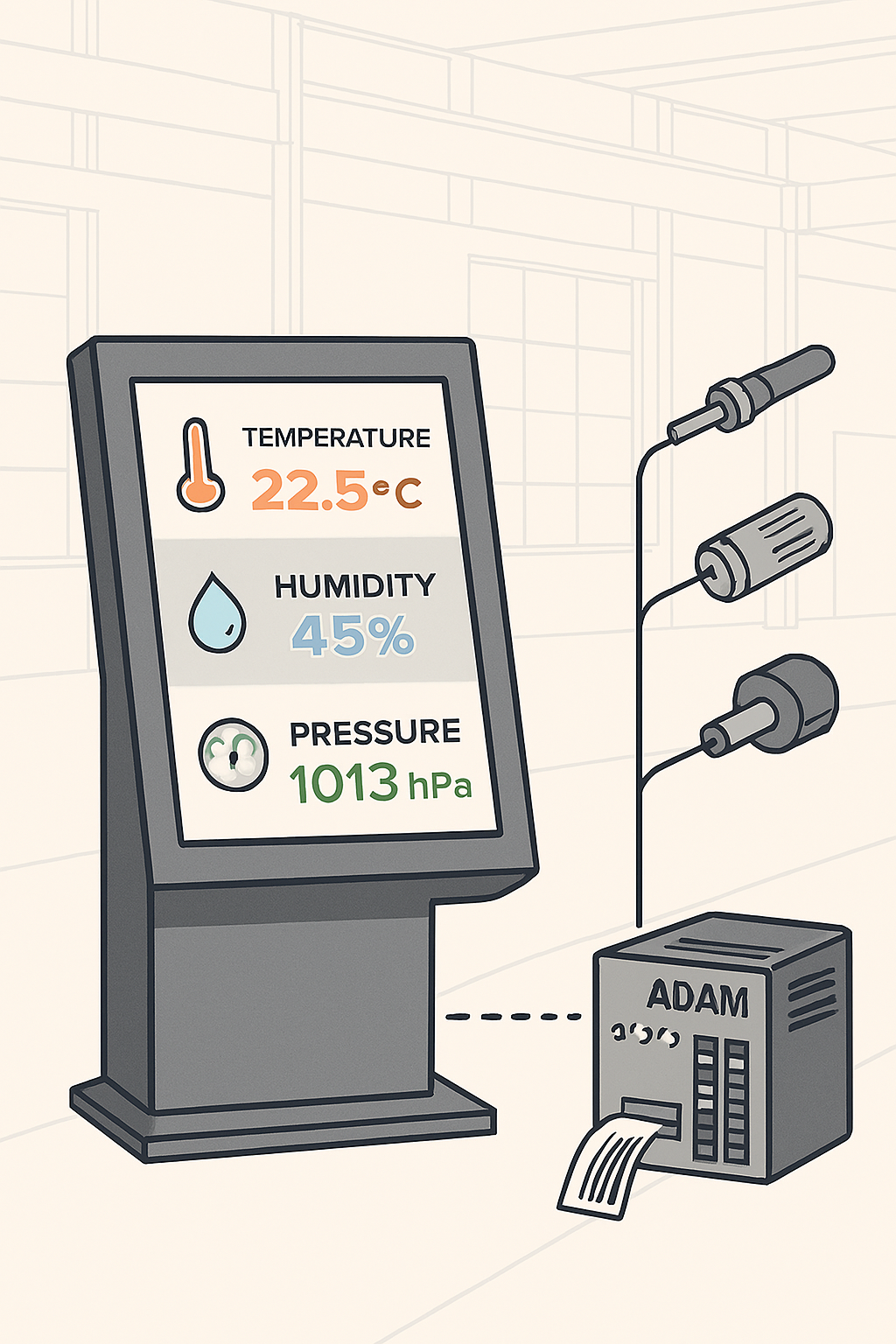

Hardware & Sensors

Rich sensor and I/O support to connect factory floor signals to higher level systems.

Details

- Inputs: up to 14 digital 5V (3-wire) inputs with configurable pull-ups and debouncing.

- Analog: optional ADC modules for temperature, pressure and process measurements (0–10V, 4–20mA support via shunt/conditioning).

- Expansion: modular I/O expansion via industry-standard modules (fieldbus or Ethernet I/O such as ADAM/Advantech modules supported).

- Sampling & filtering: configurable sampling rates and software filtering to prevent noise-induced events.

User Interface

A modern, web-enabled user interface accessible from PC, mobile, or tablet and designed for quick operator onboarding and secure access.

Technical stack & features

- Frontend: responsive web UI with live dashboards using WebSocket connections for real-time updates.

- APIs: RESTful API (JSON) plus event streaming for integration to MES, ERP or analytics platforms.

- Security: role-based access, password policies, audit trails and TLS for all web traffic.

- Customization: configurable dashboards, custom forms, and exportable reports (CSV/PDF).